SATA-GF-M13

General Description of SATA-GF-M13

SATA-GF-M13 flux is a synthetic anhydrous carnallite inorganic salt fused together by different proportion, which has multi-functions in one, such as refining, drossing, covering, degassing, etc. SATA-GF-M13 flux is excellent in removing non-metallic inclusions (oxides, carbides and borides) and alkali metals (Na, Li, Ca) from molten aluminum and aluminum alloys. An eutectic can be formed to make the melting point of fluxes lower than 480 ℃. There is none sodium content in SATA-GF-M13, so as to avoid the phenomenon of “sodium brittle”. SATA-GF-M13 flux is environment-friendly with less fume and dust, which conforms to Emission Standards of Environmental Protection Agency (USA).

Application of SATA-GF-M13

-

Suitable for 1xxx/5xxx/6xxx aluminum alloys

-

Used to remove non-metallic inclusions in molten aluminum

-

Compared with M11 and M12 , M13 is featured with excellent performance on removing alkali metals

-

By Injector with inert gas can improve degassing, reduce metal porosity, achieving high refining performance

-

Obtain dry and loose drosses

Advantage of SATA-GF-M13

-

Prevent furnaces, launders, in-line degassors and casting nozzles from piling sludge and slag

-

Less dust and fume, and low dosage

-

Reduce metal loss

-

Low melting point for rapid dispersion

-

Improve mechanical and casting properties of aluminum alloys, and improve their quality

Specification of SATA-GF-M13

-

Furnace temperature: 680-720℃

-

Dosage: 0.25-1.2kg/MT

-

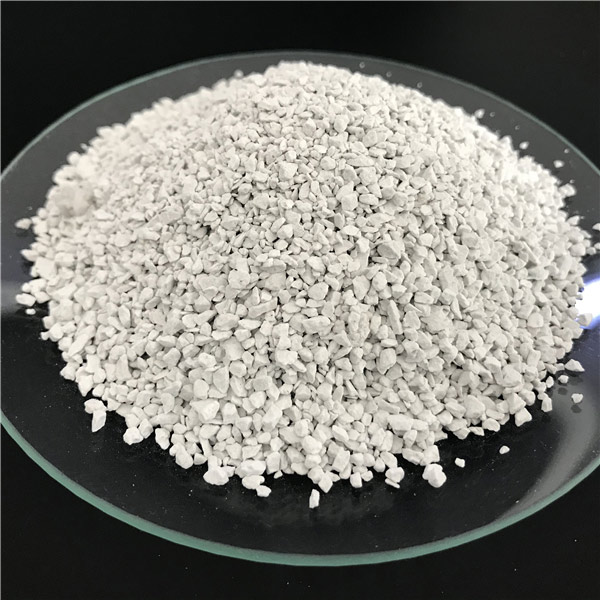

Appearance: off-white granule

-

Grain size: 1-3mm/0.8-3.25mm/1-2.5mm

-

Shelf life: 12 months

Package of SATA-GF-M13

-

Packed in 5kg (PE), 25kg (PP), 1000kg bags or customized.

-

Stored in dry, well-ventilated place, and avoid direct sunlight.