|

Grade |

Main composition(%) |

||||||||

|

MgCl2 |

KCl |

BaCl2 |

CaF2 |

NaCl |

MgO |

special material |

H2O |

other |

|

|

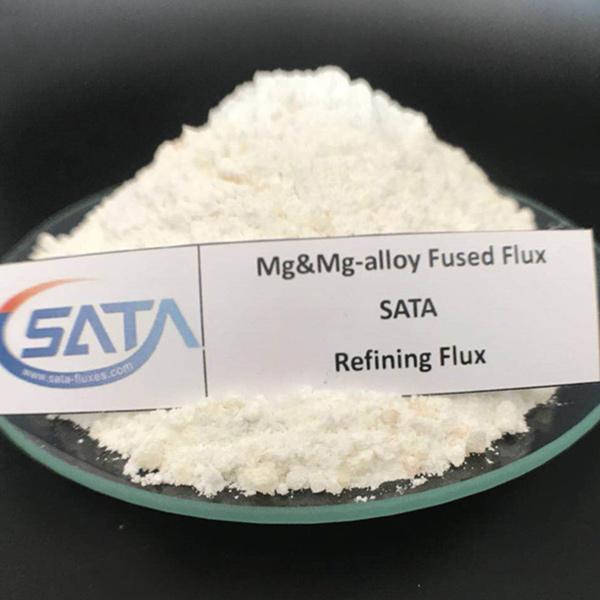

Refining flux |

40±3 |

30±2 |

5±2 |

10-15 |

5±2 |

3±2 |

5 |

<1.5 |

|

we will contact you within 24 hours.